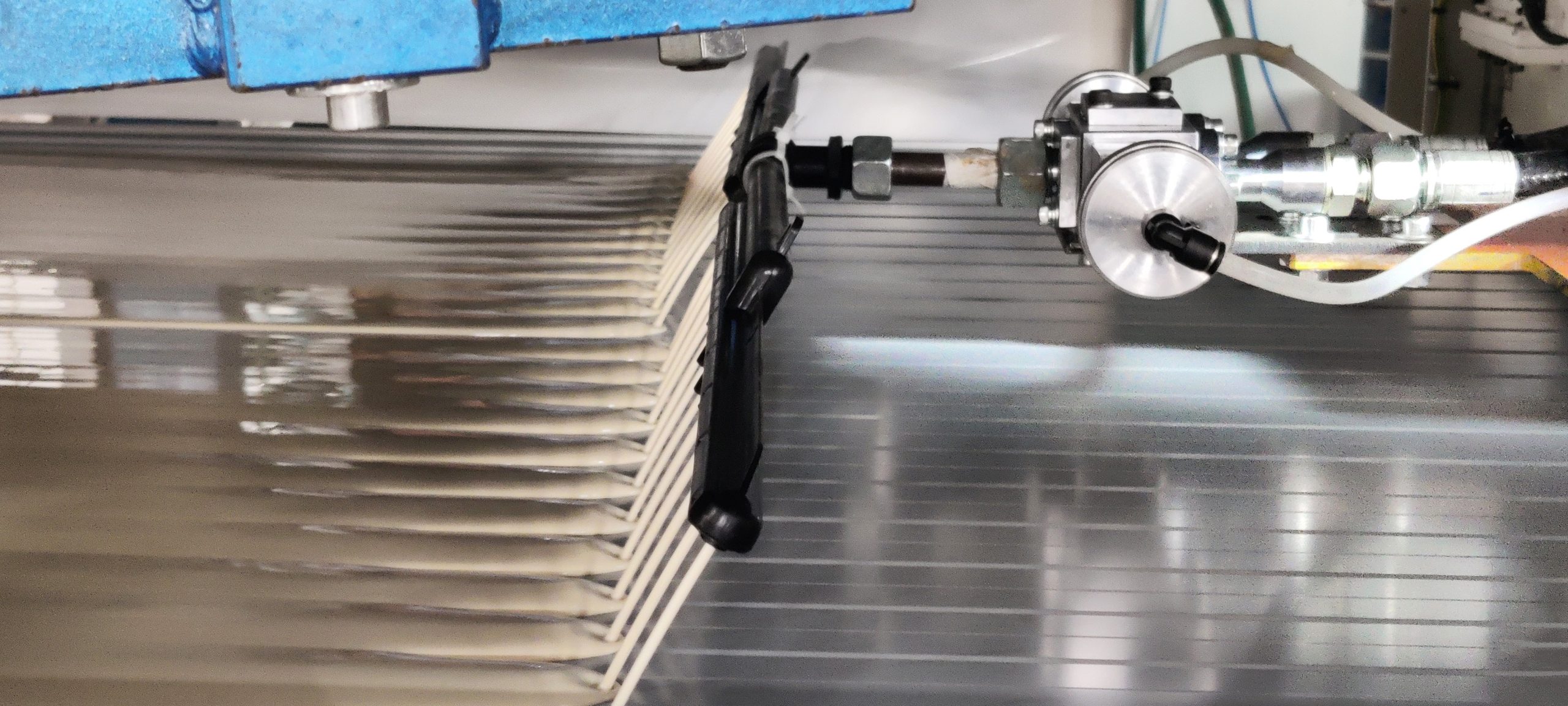

CONTINUOUS PU SANDWICH PANEL PLANT

Rim Polymers is able to supply Turnkey Continuous PU Sandwich Panel Plant for building, roofing, and cold storage applications. This includes metal roll-forming, PU foaming machine, press, cutter, storage tanks, etc.

Solutions

» PU High Pressure Foaming Machines suitable for either “Batching” or “On-line” continuous mixing system

» Equipment exclusively designed for running on C5 have all safety features and accessories necessary for using PUR or PIR systems

» Chemical Storage Tanks with temperature conditioning and re-circulation pumping system

» Enhanced heating system for special chemical system required

» Distinct 2-Zones Thermo-regulator for Tank Groups

Rim state-of-the-art PU foaming machines deliver unmatched accuracy in mixing, dispensing, and curing polyurethane foam for continuous sandwich panel lines.

» Advanced controls enable real-time monitoring and adjustments, maximizing efficiency and product consistency.

» Compact, durable, and energy-efficient, our machines cater to PUR, PIR, and rock wool cores.

» Elevate your panel quality with reliable, eco-friendly foaming technology—trusted by global manufacturers.

Tank Group

» Accurate and Consistent Temperature Management

- Large 500-liter jacketed day tanks for Polyol (PUR / PIR) & MDI

- Low pressure gear pumps for continuous feeding of chemical to metering pump and also recirculation for better temperature conditioning

- Plate type heat exchanger

- 270-liter day tank equipped with a plate-type heat exchanger for precise temperature control

» Electronic Level Management System

» Motorized Self-cleaning filter for minimal maintenance and effortless operation

Metering Group

» Precise metering and monitoring system installed with magnetic coupling to reduce maintenance and enhance operational safety

- High pressure axial piston pumps for MDI & Polyol

- High pressure dosing pump for catalyst and pentane

- World renowned German brand Mass flowmeters for accurate and reliable flow measurement

» High pressure multistage premixing of all components to ensure homogeneous mixing

- Closed-loop controlled components like polyol, catalyst, and pentane go through multistage premixing, resulting in better foam quality.

- High pressure nucleation of Nitrogen or Air for enhanced foam properties

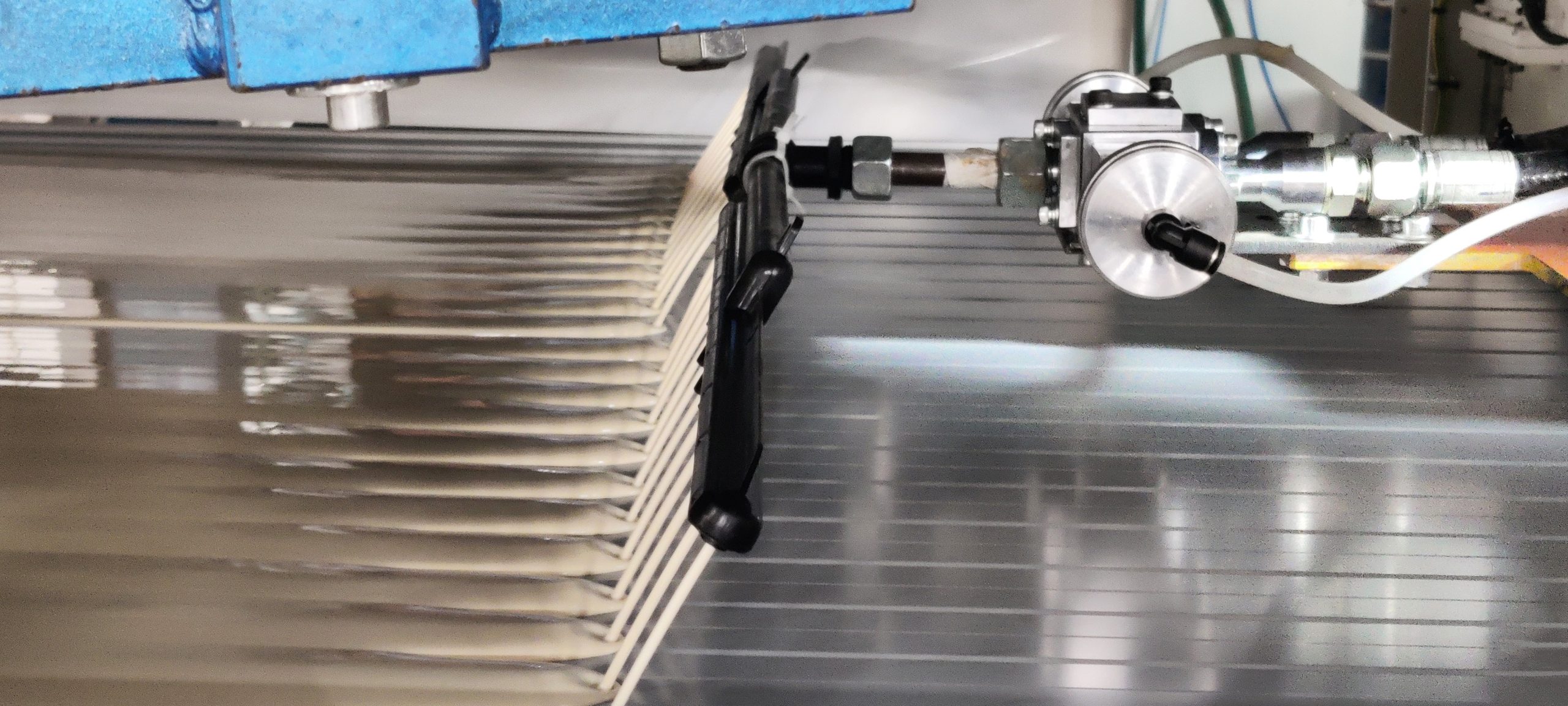

Mixing Head Group

» Laminar flow of homogeneously mixed chemical

» Remote adjustment of mixing pressure

» The mix head supports both oscillation and fixed pokers

» Servo driven oscillation movement

» Motorized longitudinal movement

Benefits

Zero Maintenance

The PU High Pressure Machine is equipped with magnetic coupling fixed onto German High Pressure axial piston (for both ISO or Polyol) to ensure no chemical leakage, and clean working environment in the factory.

“Green Energy” Saving Function

Such feature automatically cut off electrical supply to motors and pumps after pouring.

Chemical Temperature System

Two jacketed tanks (for both ISO or Polyol), each with an electrical stirrer and heat exchanger, allow the fastest speeding up of chemical temperature conditioning process in the PU industry. It ensures the proper control and circulation of chemicals, there fore maintaining the right temperature for optimal mixing outcome.

Accurate Mixing

Superior quality metering pumps and high precision flow meters are meticulously designed to comply with the parameters set. GMA L-style mix heads provide quality mixing under the right temperature, ratio and pressure setting for greatest possible end product quality.

Global Technical Service and Spare Parts Support

Ample spare parts are available for after sales support at appointed overseas locations. Headquartered in Singapore, we have an extensive global service network where there is a continuous supply of spare parts at appointed locations.